Craftsmanship

CRAFTSMANSHIP

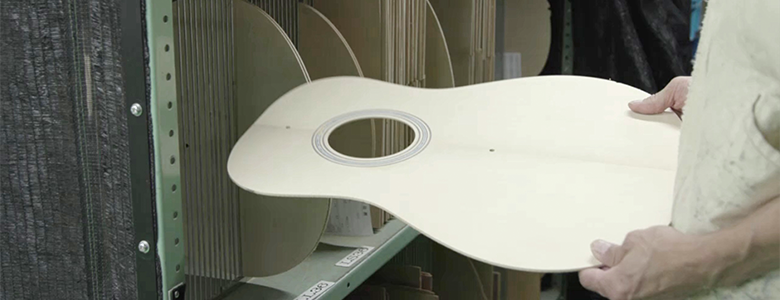

Even with advanced manufacturing techniques, it isn’t possible to automate the production of great guitars. The complexity of the task, combined with the need for constant awareness of the materials being used and the ability to adjust for minute variations, means that there is no substitute for the skill and sensitivity of experienced craftspeople.

-

Convertir diseños en grandes guitarras

Hacer que los diseños se conviertan después en grandes instrumentos no es fácil. Los dibujos técnicos no pueden reflejar el sonido esperado de un instrumento, ni tampoco la metodología de construcción necesaria para crear las características y el sonido deseados. Antes de que pueda empezar la construcción de una nueva guitarra, los planes e intenciones de los diseñadores se discuten con los artesanos que la van a fabricar para desarrollar un proceso de producción apropiado. Cada guitarra es diferente, y conseguir la metodología y el flujo de trabajo ideales para la producción de cada guitarra es vital.

-

Nos excedemos

Algunas veces, "excederse" con las cosas es la única manera de asegurar que se consigue la calidad deseada de manera consistente y en todas las situaciones posibles. En muchos casos, Yamaha lleva al extremo los detalles en el proceso de fabricación, pero los resultados finales demuestran que merece la pena. El proceso de Yamaha de acoplar previamente los cuerpos y los mástiles de las guitarras acústicas antes de acabarlas, es decir, emparejándolos al principio del proceso de fabricación, es un ejemplo. La experiencia nos ha demostrado que la calidad de la unión mástil-cuerpo juega un papel importante a la hora de maximizar el sonido y la respuesta del instrumento; en síntesis: el encaje debe ser perfecto, con un contacto íntimo entre el mástil y el cuerpo. El nivel de control y consistencia que se deriva de construir y acabar el mástil y el cuerpo como una "pareja inseparable" bien merece la pena el esfuerzo extra.

-

La combinación ideal entre maquinaria de precisión y pericia humana

Hay algunas tareas que es mejor dejárselas a las máquinas, en particular aquellas que requieren precisión extrema y repetitividad; por ejemplo, cortar las ranuras de los trastes en el diapasón es un trabajo crítico que se lleva a cabo mediante maquinaria de precisión controlada por ordenador. Pero para poder ofrecer instrumentos que realmente respondan a las necesidades de los guitarristas, hay elementos que requieren una atención individual además de flexibilidad. Y aquí es donde verdaderamente destacan los conocimientos y la experiencia de los artesanos de Yamaha.

-

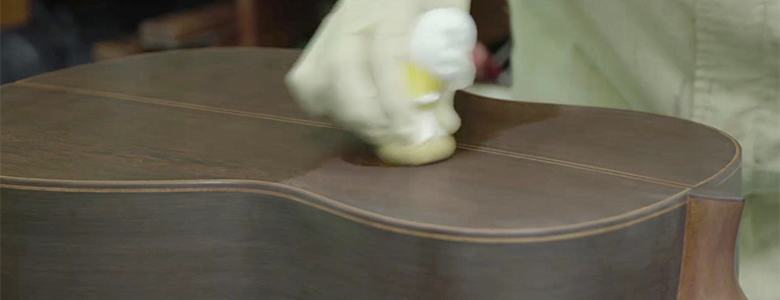

Los toques finales

En Yamaha trabajamos duro para asegurarnos de que todas las guitarras y todos los bajos salen de la fábrica en condiciones óptimas para ser tocados. Es posible que algunos músicos quieran hacer ajustes menores para adaptar su instrumento a su forma personal de tocar, pero los detalles importantes como el nivelado de los trastes y el acabado se tratan en nuestras fábricas al nivel de instrumentos "custom shop". El montaje final es un paso que requiere sumo cuidado si se pretende un sonido y unas prestaciones óptimas. Partes que no estén alineadas adecuadamente o sólidamente unidas pueden degradar tanto el sonido como la usabilidad del instrumento, por lo que las estaciones y los procesos de montaje están diseñados y configurados para que el montaje resulte eficiente y fluido, de manera que el constructor puede concentrarse plenamente en conseguir unos resultados perfectos.

-

La fabricación de las herramientas

La mayoría de las herramientas para fabricar guitarras tienen que ser hechas a mano con ese fin, y muchas se crean específicamente para un único modelo y no se utilizan para nada más. El desarrollo de herramientas y plantillas que facilitan la labor a los constructores de guitarras para producir instrumentos perfectos de manera consistente es un elemento importante en el enfoque artesano de Yamaha, pero las herramientas y las plantillas pueden desgastarse y desalinearse con el uso, así que ponemos un cuidado especial en mantenerlas en perfectas condiciones operativas en todo momento; son una parte que no se ve, pero fundamental para el control de calidad.

-

Mantener viva la artesanía

Dada la importancia que tienen los conocimientos de artesanía en la fabricación de buenas guitarras, la única forma de garantizar una calidad consistente y continuada en el futuro es traspasar el "know-how" a la próxima generación de artesanos. Esta clase de destreza solo se puede traspasar plenamente de persona a persona, a través del aprendizaje práctico, por lo que Yamaha hace de ello una parte oficial del proceso de fabricación de guitarras. El equipo de constructores de guitarras cambia con el tiempo, pero Yamaha se encarga de garantizar que los conocimientos básicos, así como las muchas innovaciones desarrolladas a lo largo de los años, se traspasen de manera efectiva para que nuestras guitarras puedan continuar evolucionando.

-

El proceso de fabricación de una guitarra